-

About UsProductsCustomized SolutionProjectGalleryNews

Woven mesh fabric: Advancements in Digital Fabrication and Design Integration

Release time: September 21, 2023Digital Manufacturing Advances: With the development of digital technology, the manufacturing of woven mesh fabrics has been greatly improved. Digital technology makes the acquisition, analysis and utilization of data in the production process more accurate and efficient. By using computer-aided design (CAD) and production management systems (PMS), manufacturers can achieve precise control of the production process and improve production efficiency and product quality.

Intelligent development: Woven mesh fabrics have made significant progress in intelligence. By integrating sensors and smart chips into fabrics, manufacturers can monitor and collect various performance data of fabrics in real time, such as breathability, warmth, strength, etc. This data can provide designers with an important reference to help them better understand the performance of fabrics and optimize design solutions.

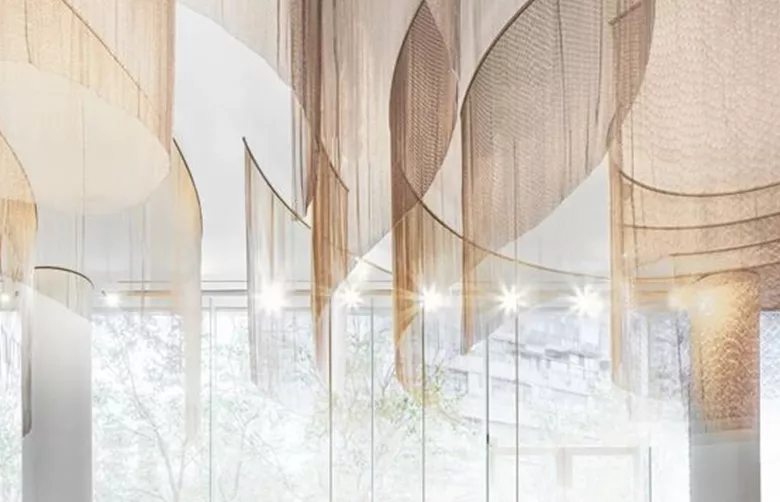

Design innovation: Innovation in design and aesthetics of woven mesh fabrics has also been greatly developed. Designers can use digital technology to create more complex and sophisticated designs, achieving diverse textures, patterns and color combinations. At the same time, designers can also explore new fabric structures and properties by working closely with materials scientists and engineers to further expand the space for design innovation.

Customized solutions: The development of woven mesh fabrics makes customized solutions possible. Through digital technology, manufacturers can quickly and accurately obtain customer needs and customize them according to customer requirements. This kind of customized service not only increases the added value of the product, but also provides customers with a better experience and meets their pursuit of uniqueness and personalization.

Recommended News